Inhouse

The production of the molded foam components takes place on approx. 2,500 square meters within the company Pi-Products GmbH. Pi-Products GmbH was founded in Amberg in 2001. The integration into our group of companies took place in 2019.

Cut foam components are handled by the company Weserland Sitzsysteme GmbH. Weserland Sitzsysteme GmbH was founded in 2002 in Calden, near Kassel, and integrated into the metz group in 2020.

Foam systems

We have successfully used all foam systems available on the market. Here are to be mentioned: Rigid foam, integral skin foam, flexible foam, casting system, RIM and visco. In particular, we also use flame retardants and thus meet many DIN standards and legal requirements for our customers.

- Hard foam

- Soft foam

- Integral foam

- Prototypes, small series, series

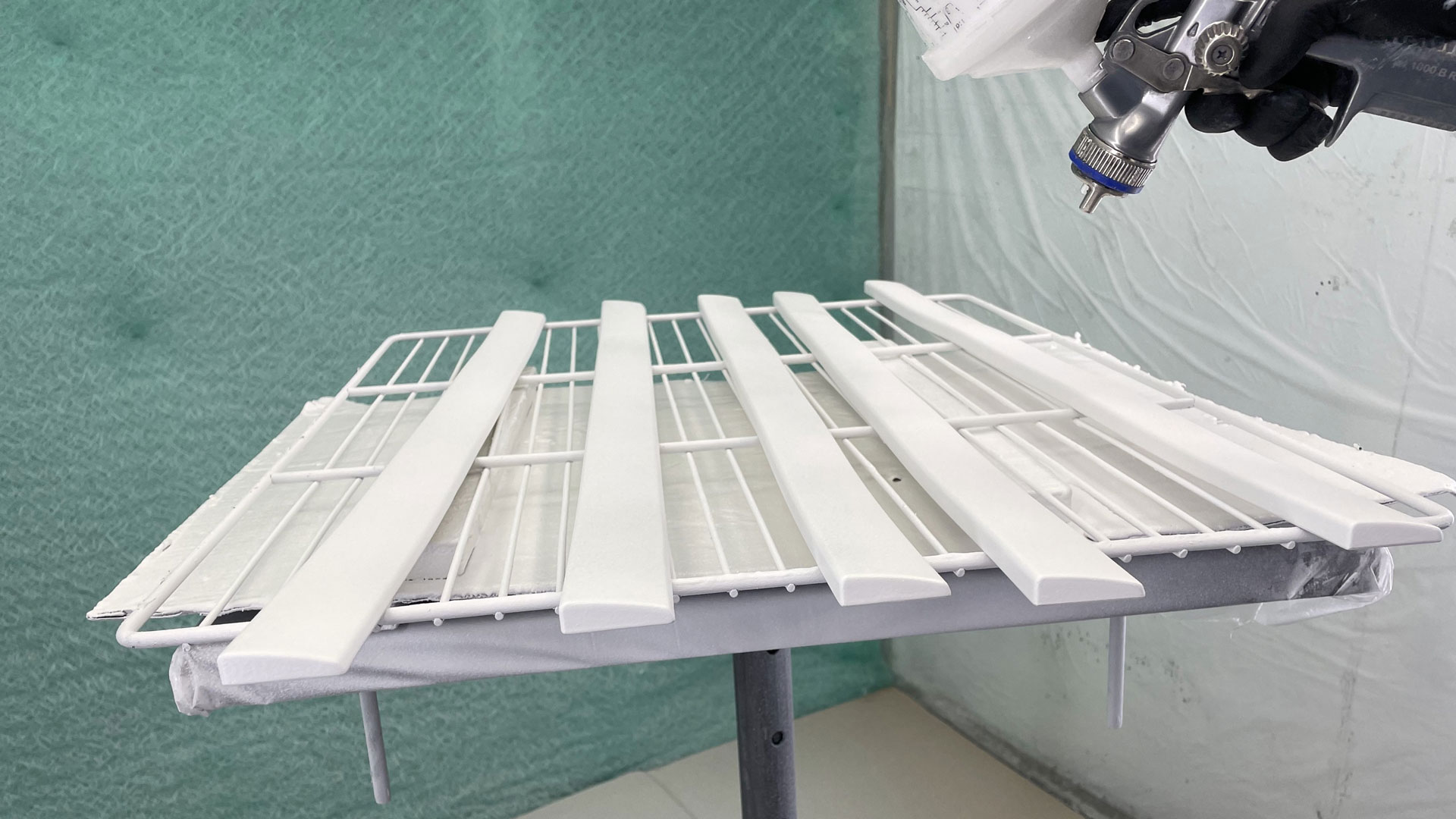

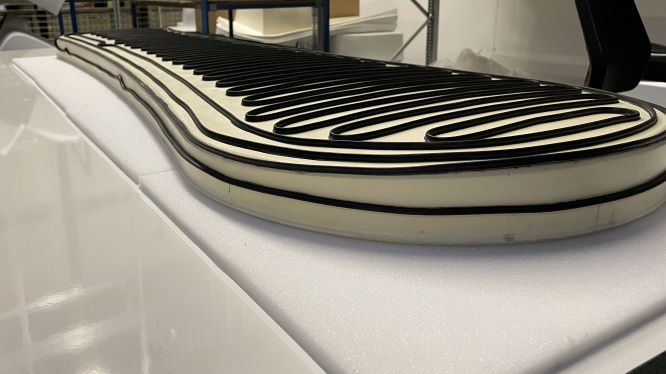

Surfaces

We are experts in painting polyurethane molded foam parts. We paint in a variety of colors, paint systems and textures. Many of our linings, covers and overlays can be found in medical technology. We have our in-house paint department, which significantly reduces lead times for our customers. Our portfolio includes standardized two-component painting in combination with product-specific and very complex paint preparation. In addition to the often challenging surface treatment, we can also sandblast substantial components. In addition, we also offer our customers PU coatings for flexible foam moldings.

- Paint preparation

- Two-component coatings

- IMC coatings

- PU coatings of flexible foam moldings

Cut foam

We manufacture foam articles and combined them with other foam qualities of materials. We have various vertical and horizontal slitting lines with revolving or oscillating band knives, which are controlled automatically or manually in our production. Furthermore, we have a CNC-controlled automatic cutting machine. Different contours are programmed. CAD data provided by the customer is converted into our cutting program.

- CNC controlled automatic cutting machine

- Spray booth for gluing work

- Finishing of foam articles with felt, absorbent cotton and fire blocker

Finish

For many of our customers, we process foamed and trimmed foam parts. Our technologies include printing, gluing and the assembly of electronic components.

- Laser printing

- electrical wiring and 100% control

- Bonding blanks