Multifunctional "Comfort and Security" seat backrest

Objective

Highly specialized and in demand in unique vehicle construction. To adapt existing, proven seat components ideally and inexpensively, a variable, complementary seat back was required: Force-fit, safe, optimized.

Technology and material

Design, finite element method (FEM), pipe bending, turning, milling, pipe forming, laser cutting, edging, fixture construction, welding

Remarkable

The result is a multifunctional backrest consisting of a basic unit to which a wide variety of functions (left or right seat belt connection, various headrest solutions) can be individually configured depending on the customer’s requirements.

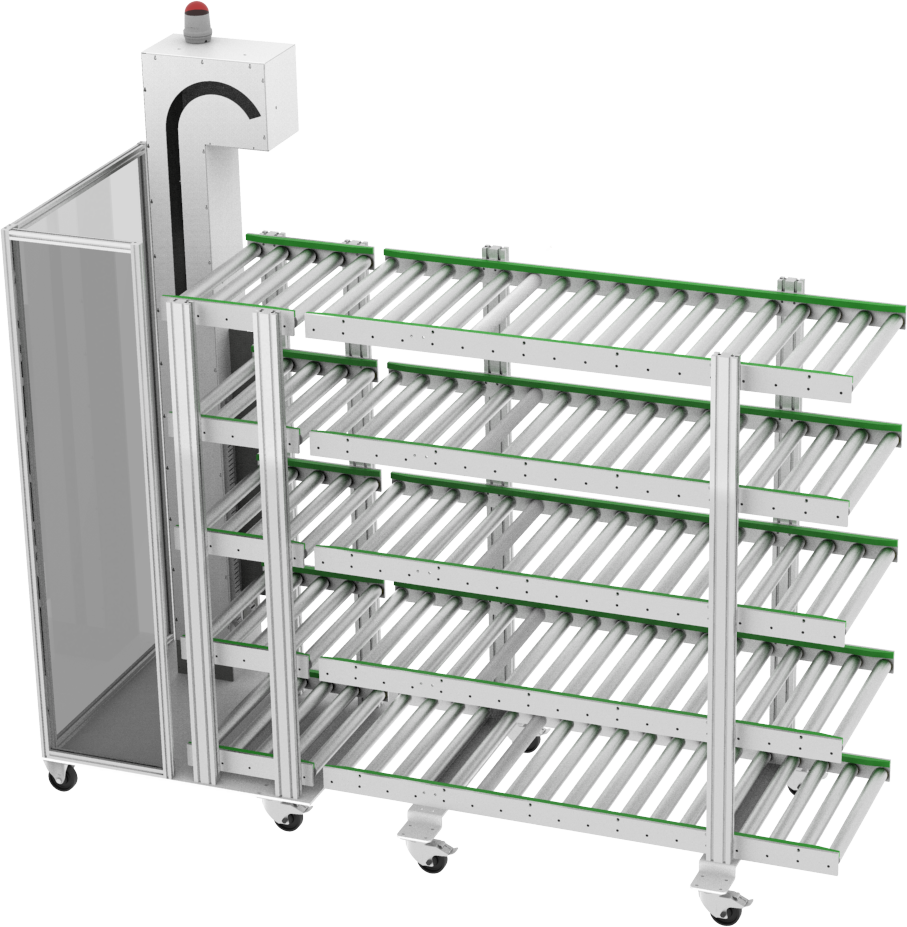

Mobile Production Master

Stabilo International GmbH is one of the leading manufacturers of writing instruments in Europe – a company rich in tradition that has constantly been developing for a good 160 years.

Objective

Our customer uses injection molding machines for its extensive, highly differentiated product range. In the best-case scenario, they are on duty around the clock, even at night and in ghost shifts without men on Sundays and holidays. To achieve this, we have refined a technically advanced standard solution. The result: An innovative, mobile, highly flexible system. It supports intralogistics, is compatible with various machines of the global player.

Technology and material

Design, machining, lasering, edging, welding, control systems, electrical wiring, control cabinet construction, commissioning and, if required, maintenance and services by our employees on site

Remarkable

The result is a two-part intralogistics system according to the customer’s wishes. Compact and space-saving for daily use, modularly expandable for unmanned machine running times. Our inventive spirit is pleased to remain on-site for maintenance and further development. And of course: Cooperation with a company rich in tradition is special, especially when innovation is so sought after and welcomed.

metz group Exacure - contact-active cladding

Objective

Our customer specialized in highly complex robotics and was looking for a partner who could deliver high-quality cladding components very quickly. After analyzing and improving existing tools, we succeeded in building and implementing a custom-fit, two-shell system at short notice that meets all requirements.

Technology and material

Mold making, foaming, assembly, bonding, finishing, painting and functional testing

Remarkable

Only a few weeks passed from the request to the implementation. Short decision-making processes and close consultation between our highly qualified team of employees have made this excellent cooperation possible.

24/7 Sitting

Cento advanced seating GmbH from the Bavarian Allgäu region specializes in high-quality, ergonomically designed office chairs, which it manufactures in series and fulfills unusual customer requests, the conversion of a Porsche 911 seat into an office chair.

Objective

A new chair is to be launched – usable 24/7 – seven days a week, around the clock. This extremely comfortable and functional chair will be used, for example, in control rooms and control stations that need to be manned around the clock.

Technology and material

Design, component optimization, foam optimization, blank determination, foaming, metal component manufacturing, painting, upholstery

Remarkable

A brand new seat concept with many innovative features and a very sporty design. Possible through short decision-making processes, creative implementation, rapid realization. And again, everything is from a single source.