Inhouse

The metal production of the metz group is handled by the company metz automotive GmbH. Metz automotive GmbH was founded in 2008 by managing director Josef Metz and is located in the northern Upper Palatinate. Metal components are designed, manufactured and finished in an area of approximately 3,000 square meters.

CNC machining

The metz group processes metal in-house with its machinery, which is programmed via CAM. We process aluminum, stainless steel, tool steel and plastics, on-demand and fast: Prototypes, single pieces, small series and large series.

- CNC turning/automatic turning up to 72 mm with driven tools

- CNC turning up to 42 mm

- Conventional turning

- 3-axis milling up to 1600 mm clamping surface

- 5-axis milling up to 750 mm clamping surface

- Profile machining up to 5m length

- Conventional milling

- Steel

- Stainless steel

- Aluminum

- Plastic

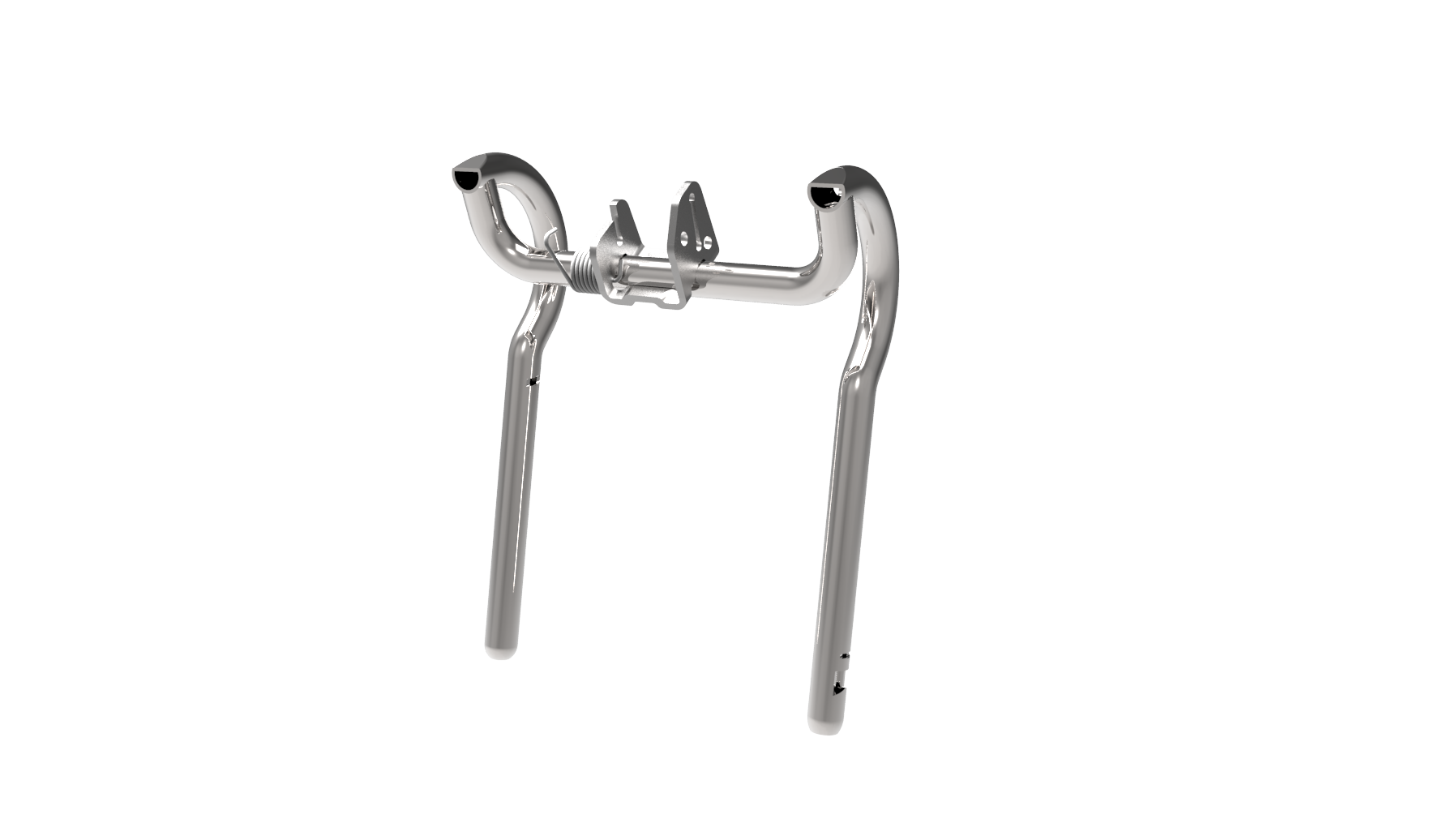

Pipe machining

We specialize in machining tubes up to 25 mm. In our workshops, we manufacture suitable tools, which allow any forming reliably and promptly—for example, headrest bars for the automotive industry - at the highest qualitative level.

- CNC tube bending

- Forming

- 3-axis milling

- 5-axis milling

- Profile machining up to 5 meters

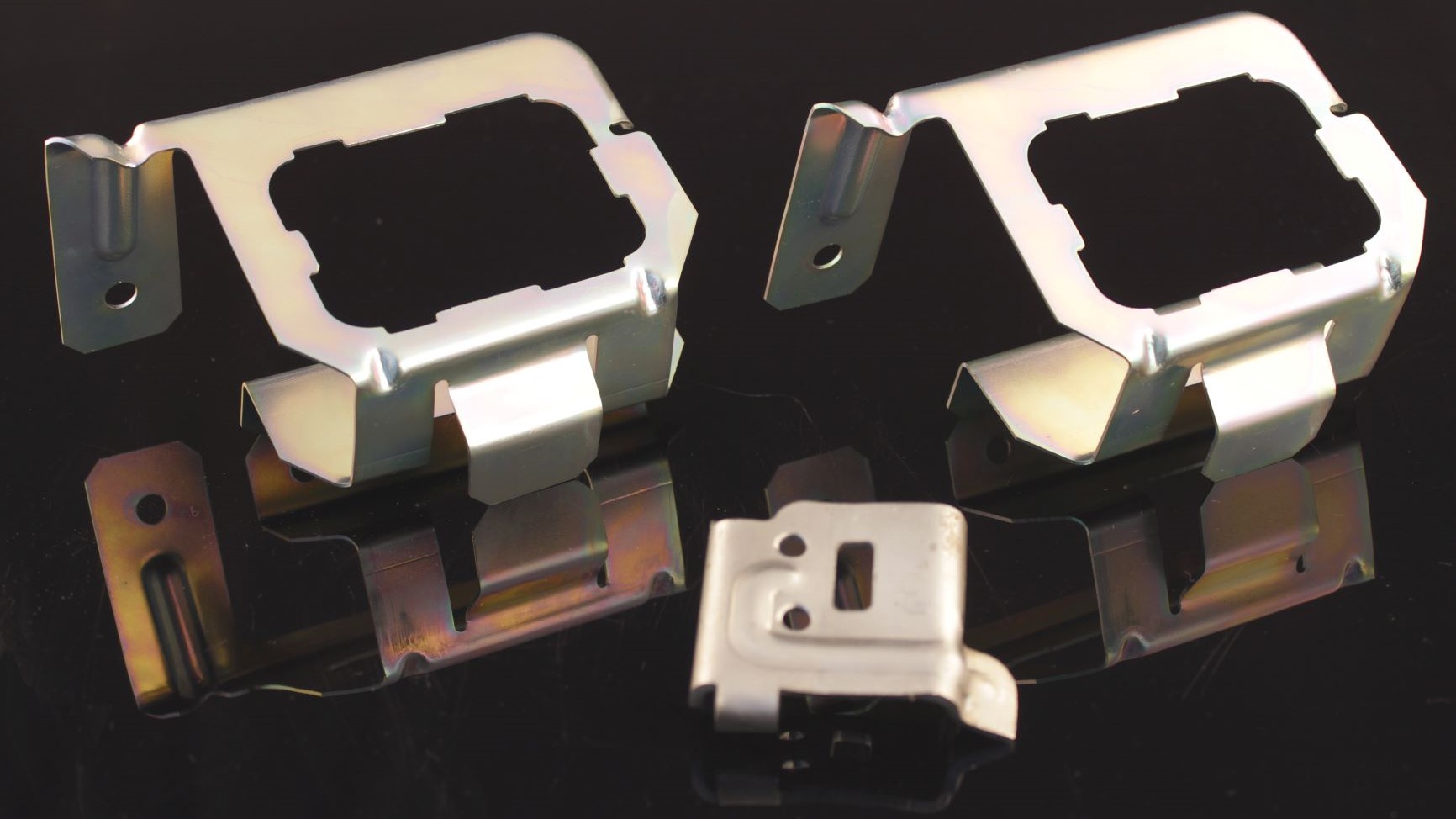

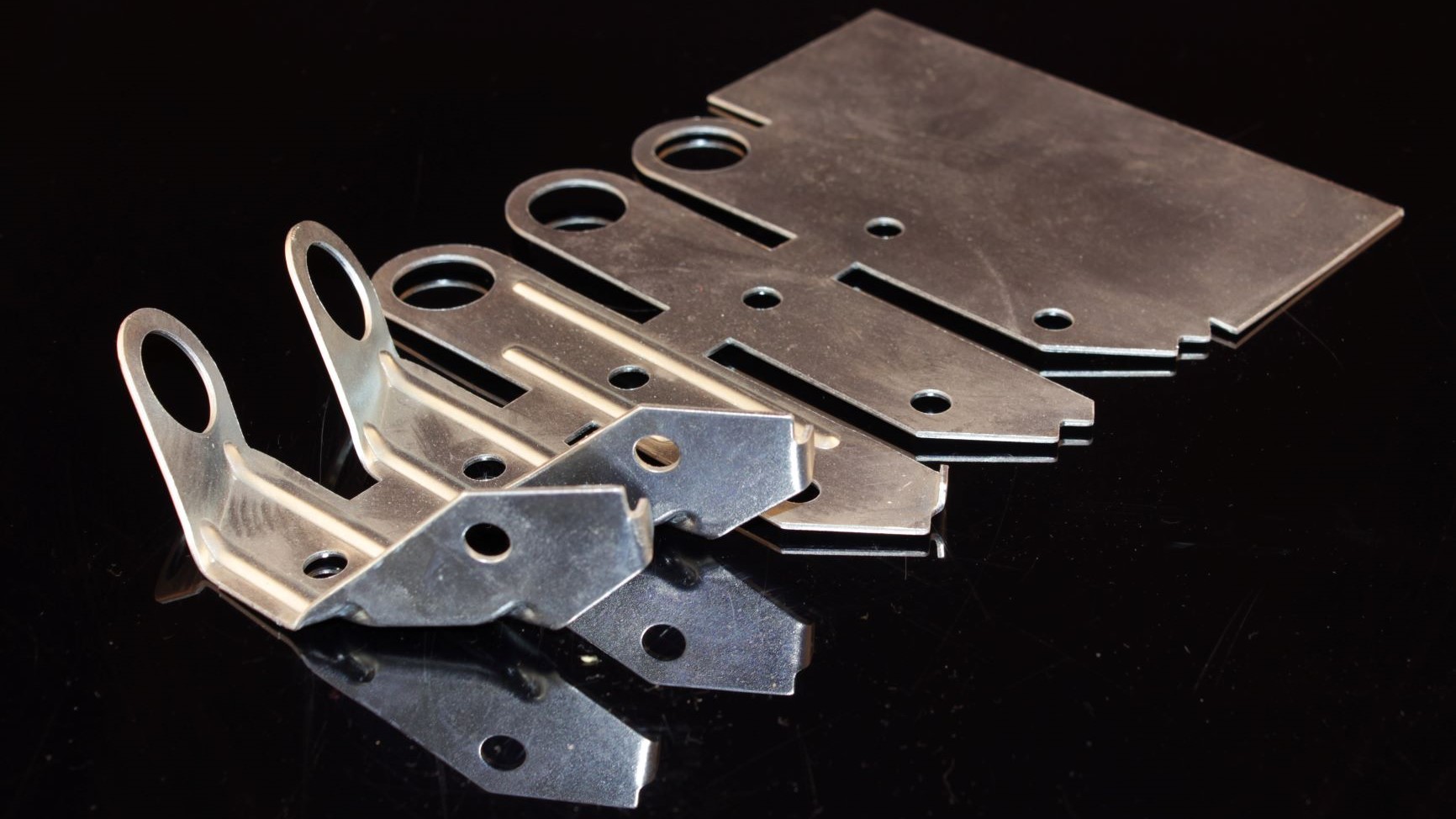

Sheet metal working

We cut edge and shape sheets of aluminum, steel and stainless steel up to a thickness of 15 mm. We cut with a powerful, precise CO2 laser, edge components and individually manufacture suitable tools for this purpose. Our special edge tools and forming tools are designed, built and fine-tuned entirely in-house by our employees from a single source. Our presses have an output of up to 100 tons.

- Laser

- Edges

- Forming

- Steel

- Stainless steel

- Aluminum

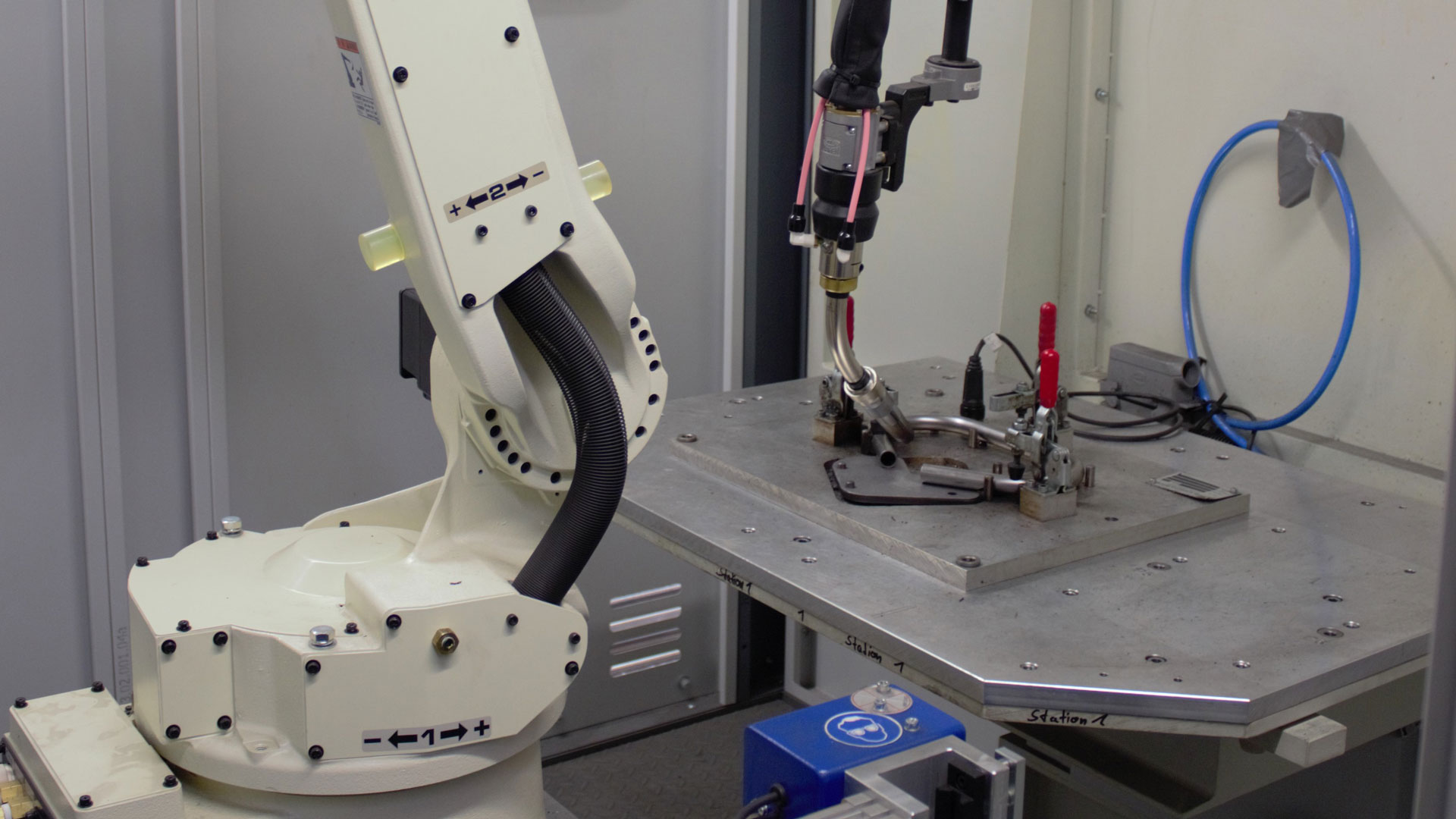

Welding

Our certified welders are state of the art in TIG, MIG and MAG processes. You are adept at working with welding assemblies made of aluminum, stainless steel and steel and use welding robots, especially for series parts. We carry out orders with projection welding with 160 kVA. We have extensive experience and certifications in the demanding rail and railroad sector (Railway/Mobility).

- TIG

- MIG

- MAG

- Robot welding

- Projection welding